Page 54 - Gulipek Sustainability Report 2021

P. 54

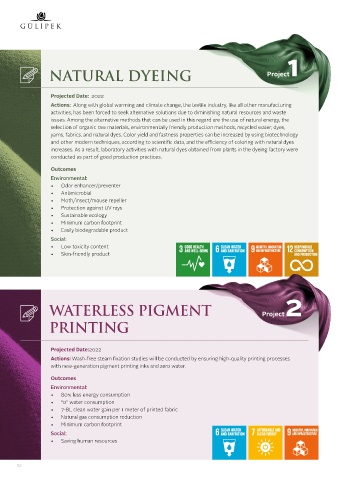

Project1

NATURAL DYEING

Projected Date: 2022

Actions: Along with global warming and climate change, the textile industry, like all other manufacturing

activities, has been forced to seek alternative solutions due to diminishing natural resources and waste

issues. Among the alternative methods that can be used in this regard are the use of natural energy, the

selection of organic raw materials, environmentally friendly production methods, recycled water, dyes,

yarns, fabrics, and natural dyes. Color yield and fastness properties can be increased by using biotechnology

and other modern techniques, according to scientific data, and the efficiency of coloring with natural dyes

increases. As a result, laboratory activities with natural dyes obtained from plants in the dyeing factory were

conducted as part of good production practices.

Outcomes

Environmental:

• Odor enhancer/preventer

• Antimicrobial

• Moth/insect/mouse repeller

• Protection against UV rays

• Sustainable ecology

• Minimum carbon footprint

• Easily biodegradable product

Social:

• Low toxicity content

• Skin-friendly product

Project2

WATERLESS PIGMENT

PRINTING

Projected Date:2022

Actions: Wash-free steam fixation studies will be conducted by ensuring high-quality printing processes

with new-generation pigment printing inks and zero water.

Outcomes

Environmental:

• 80% less energy consumption

• “0” water consumption

• 7-8L clean water gain per 1 meter of printed fabric

• Natural gas consumption reduction

• Minimum carbon footprint

Social:

• Saving human resources

52